Home › Forums › BD-5 Builders Forum › Jet Engine Installation › Noel Penny Turbines NPT301

- This topic has 9 replies, 1 voice, and was last updated 1 year, 4 months ago by

Benjamin Morgan.

-

AuthorPosts

-

February 14, 2023 at 12:32 pm #644

Benjamin Morgan

KeymasterFebruary 14, 2023 at 12:36 pm #649Benjamin Morgan

KeymasterA major milestone has been achieved today, with the sourcing of partial original manufacturers documentation for the NPT304-4 engine. Not everything, but enough to start reverse engineering things.

These documents give clarity to important parameters that will enable the team to assemble an engine start control panel, along with associated accessories. Without these documents, we were in for a major headache as we tried reverse engineering the engine control computer and accessories.

The documents are confidential reports to CMC from Noel Penny Turbines, regarding their prototype experimental NPT301-3 and -4 engines. These engines were produced under contract between NPT and CMC, for the development of the CMC Leopard experimental corporate jet project. NPT went bankrupt in around 1990, and CMC followed not long after.

The only repository of documents that I have been able to track down was Volvo Aero Engines, which acquired the intellectual properties and engineering assets of NPT. Volvo subsequently sold off their small aero engines division to an Italian company, which now produce gas turbine power generators. After months of enquiries to these businesses, none are willing to supply documents – I would say legal liability concerns etc.

So, how did I manage to find these critical documents? It turns out, that in the UK there is a backyard engineering community that focus on getting old aircraft jet/turbine engines working. Some they mount to test stands, others they mount in cars, motorbikes, go-karts and trucks!

As it would turn out, there are some youtube videos of a Go-Kart with a NPT301 installed in it, and after some internet sleuthing and facebook stalking, I was able to track down the guy who owned the Go-Kart. He had acquired one engine from CMC during their sell-up, and with it obtained sufficient documentation to determine the operating limitations of the engine, along with electrical diagrams and other critical information.

February 14, 2023 at 12:38 pm #650Benjamin Morgan

KeymasterFebruary 14, 2023 at 12:39 pm #654Benjamin Morgan

KeymasterFebruary 17, 2024 at 12:18 pm #1099Benjamin Morgan

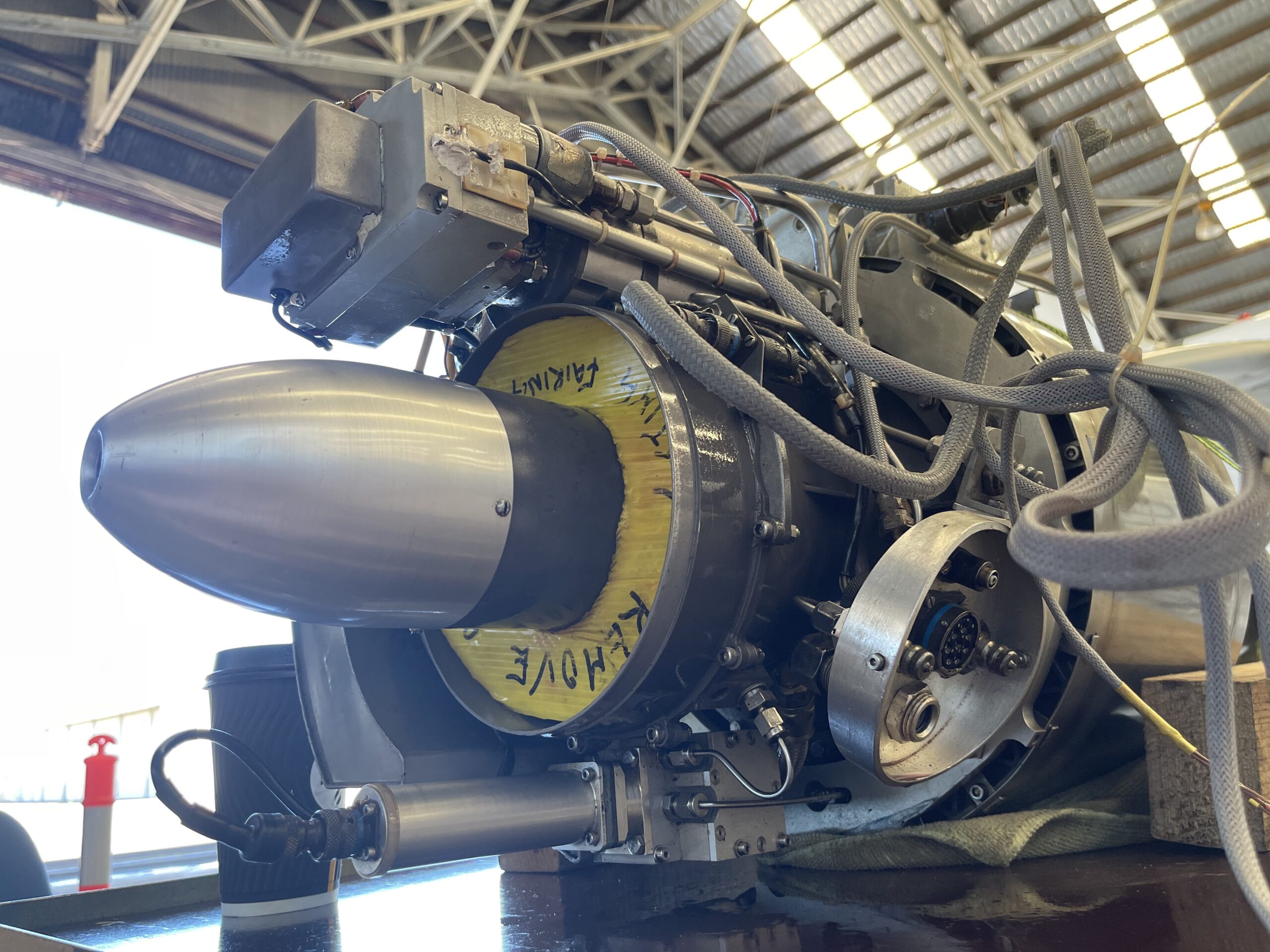

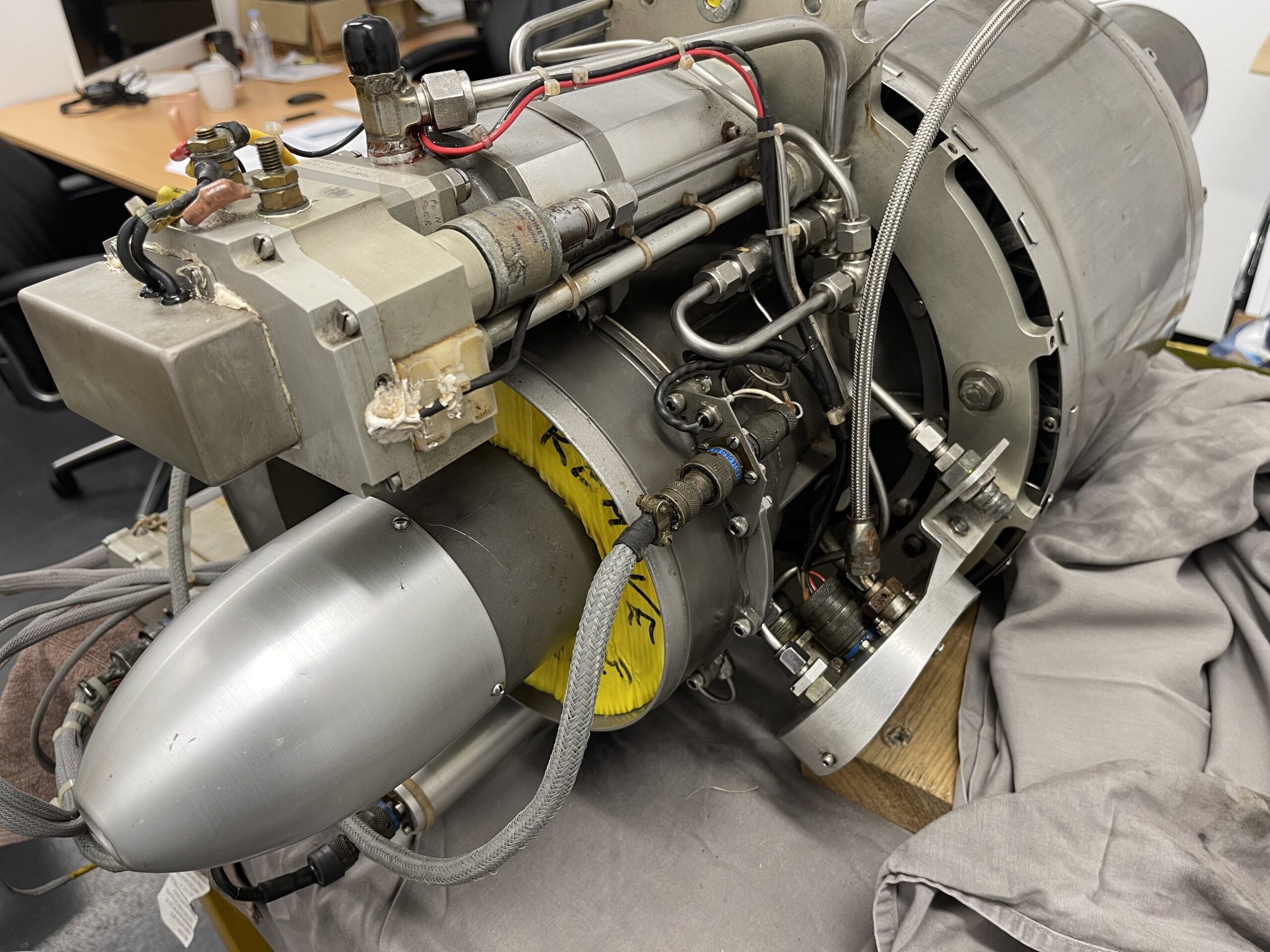

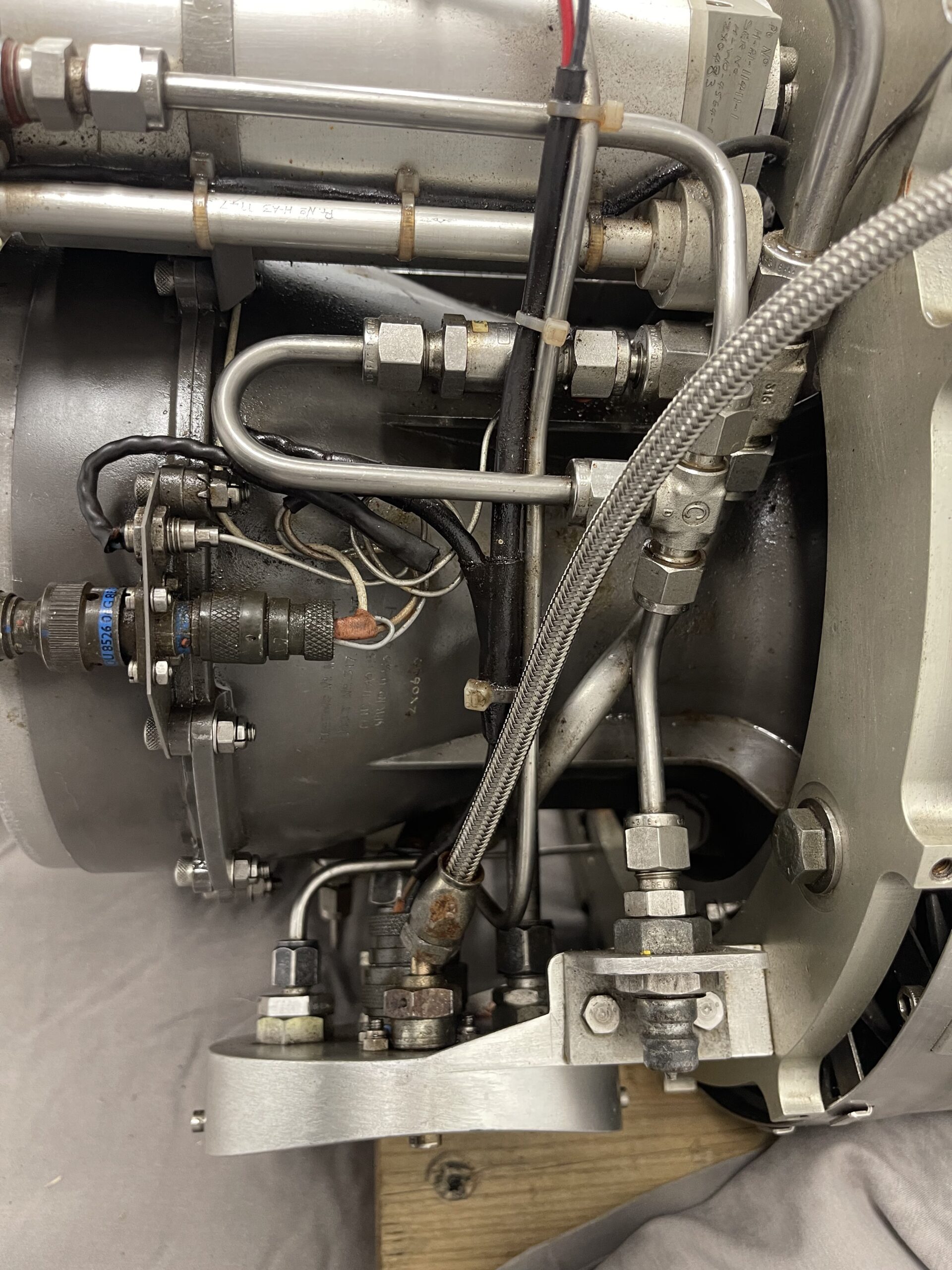

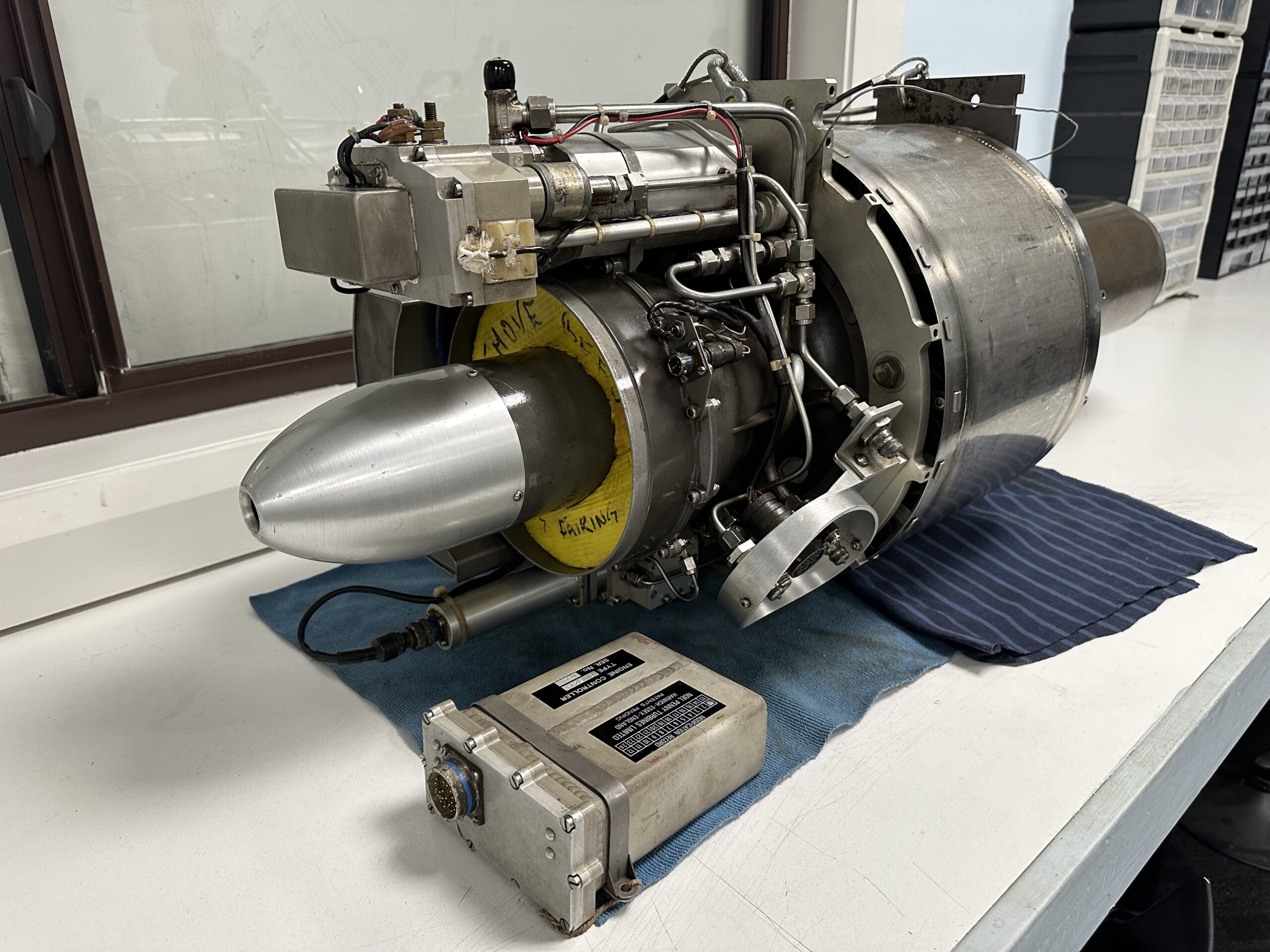

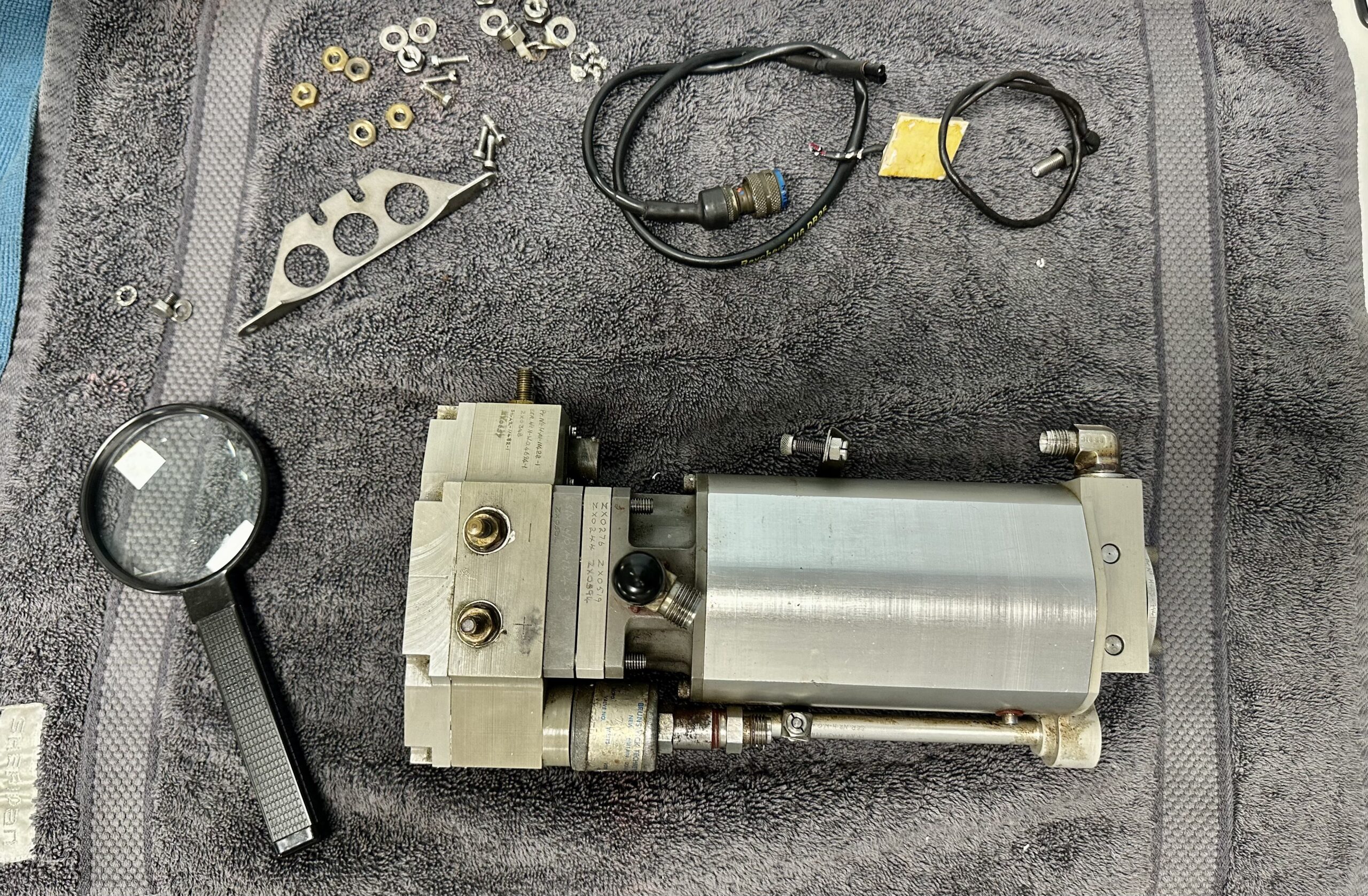

KeymasterWith things settling into the new workshop, I was able to get the NPT301 turbine back out of it’s transport case and up onto the workbench for a clean down, in preparation for our Aeronautical Design Engineer, Matthew Fortuin, to commence his work. Matthew will be producing a detailed set of drawings and plans for an entirely new fuel control system, oil system, engine control computer and other accessories etc.

This work will enable us to get rid of the heavy 1989 components (to which we have no documentation for), replacing them with modern and lightweight alternatives that are reliable and that we can service and maintain.

Another goal of the work is to reduce the overall turbine weight, which currently stands at 45kgs dry. We are confident that a 5kg reduction can be achieved.

We will also need to modify the inconel thrust tube (lengthen it 350+mm) to fit the BD5J fuselage.

February 21, 2024 at 11:36 am #1309Benjamin Morgan

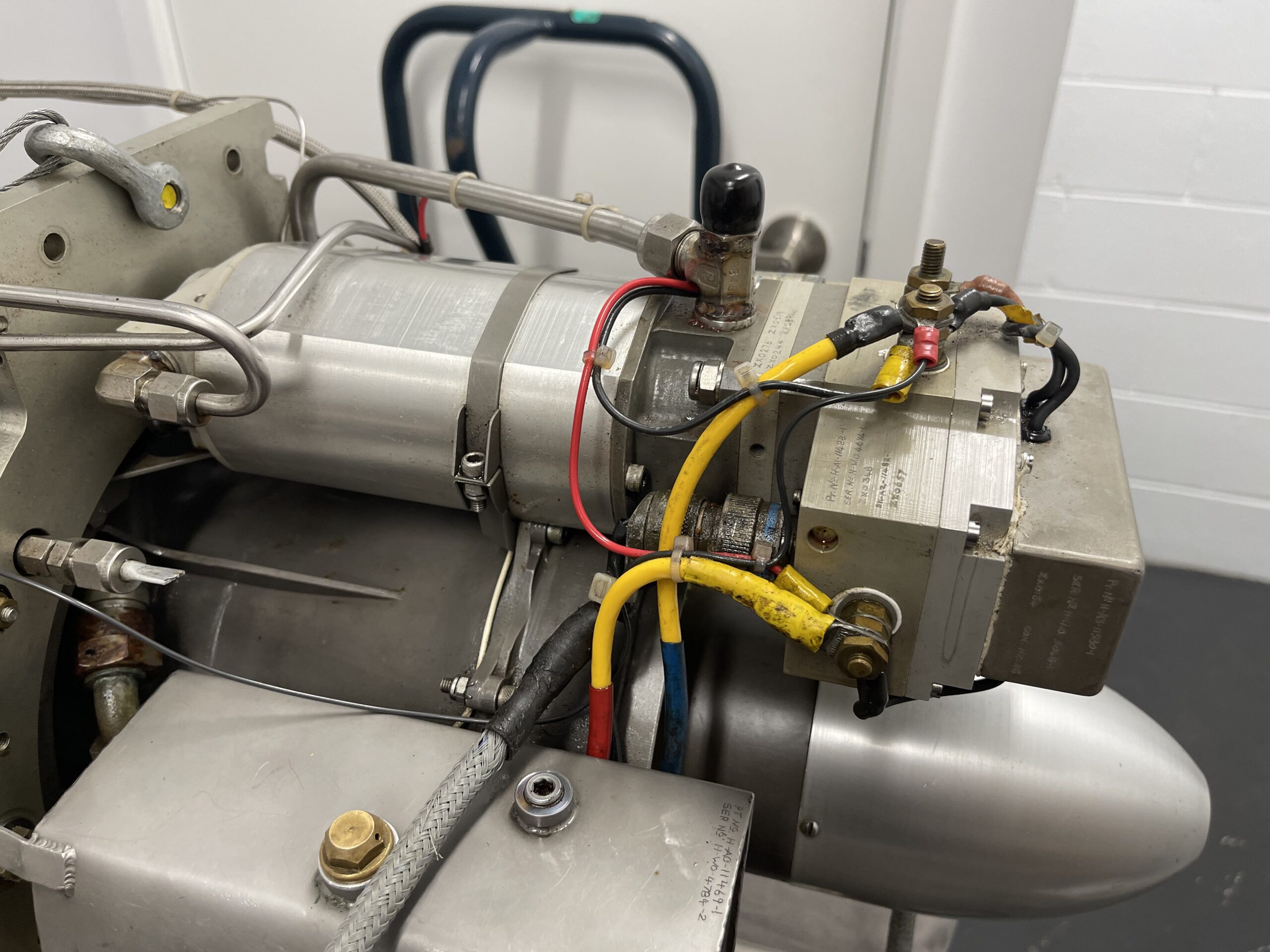

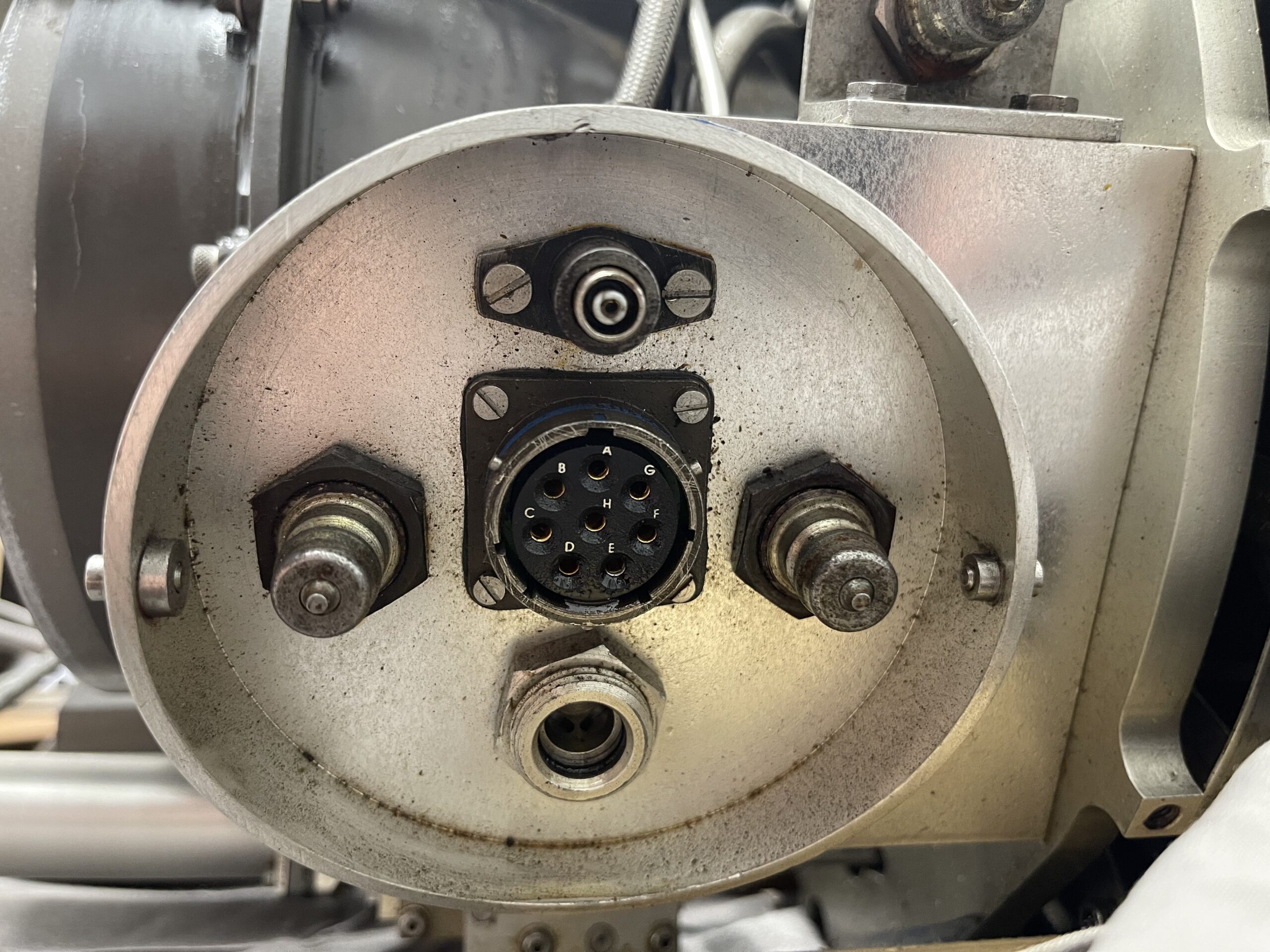

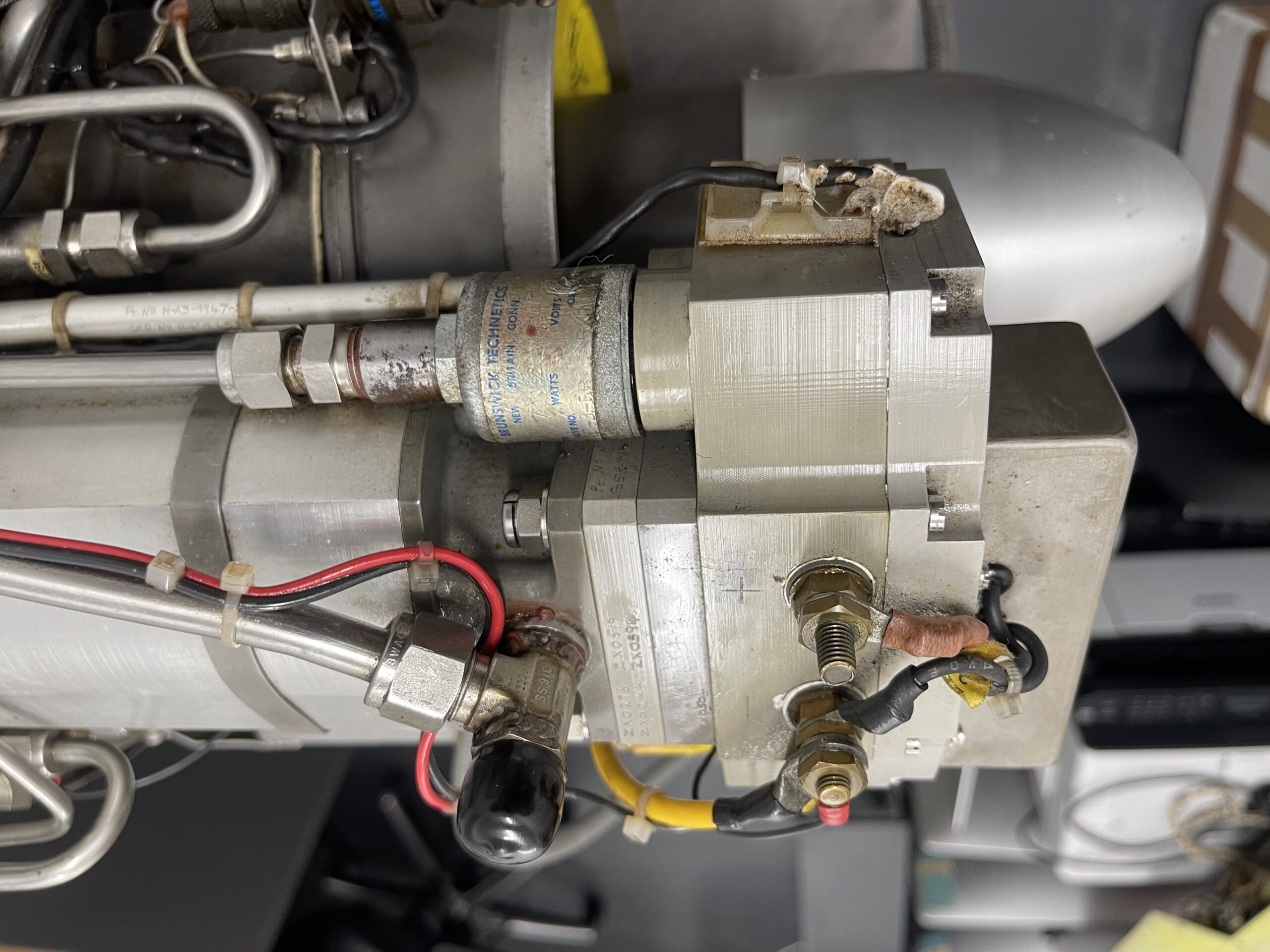

KeymasterWe removed the 28v alternator from the forward section of the turbine today.

The alternator assembly came out easy enough, after being bathed in ACF50 and gently tapping it to walk the housing back out of the stator casting. The alternator housing is stainless steel, whilst the turbine stator casting is alloy. My guessing is that the alternator had not been out of this engine since 1989, some 35 years, and some moisture has worked it’s way in there.

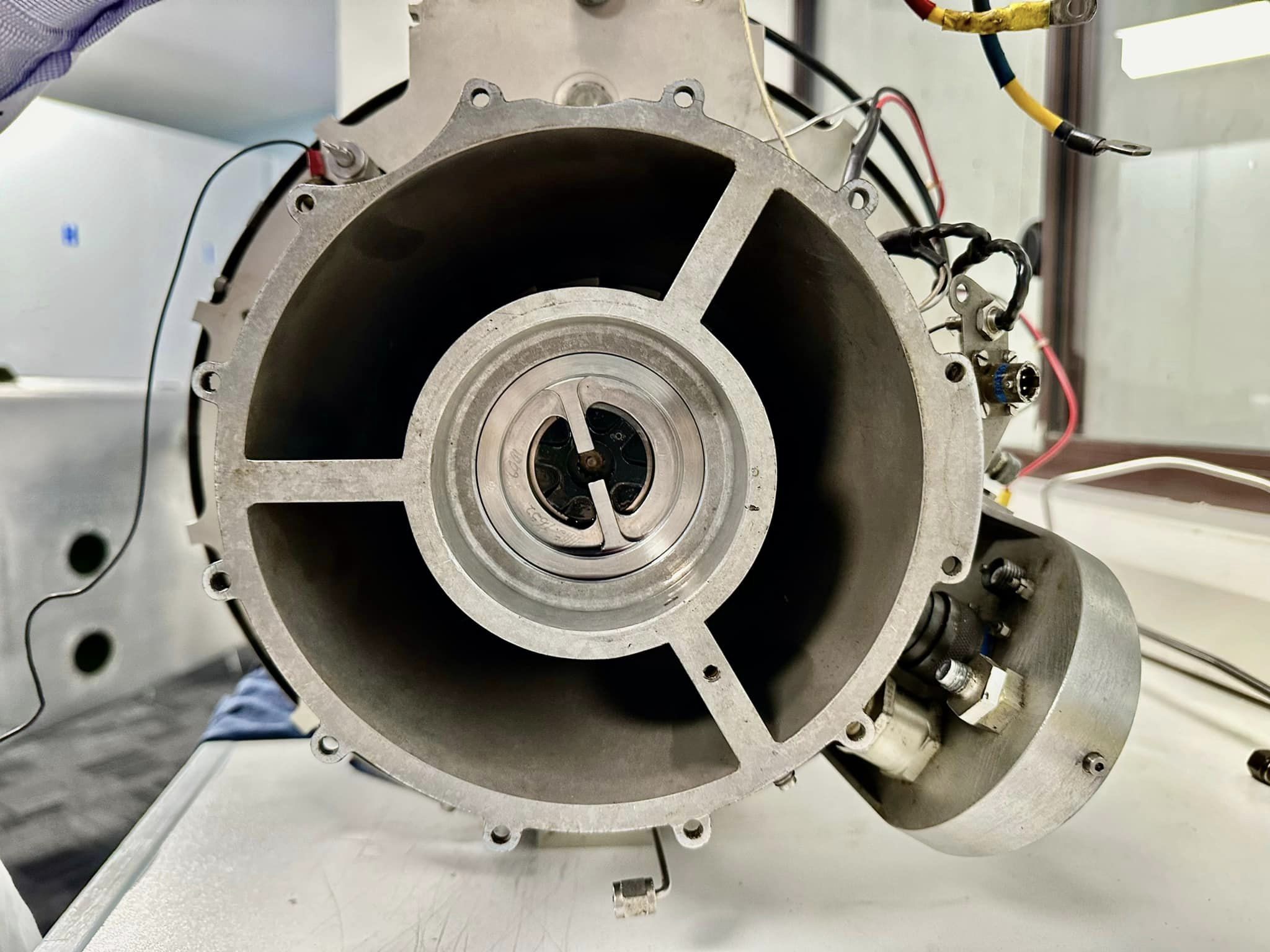

The task at hand is to remove all of the accessories and brackets, so that we can split the turbine case and remove the shaft/compressor assembly, so that we can replace the front and rear bearings. The front bearing is a ball bearing style and the aft bearing a roller pin bearing.

February 21, 2024 at 11:47 am #1315Benjamin Morgan

KeymasterFebruary 22, 2024 at 6:31 am #1322Benjamin Morgan

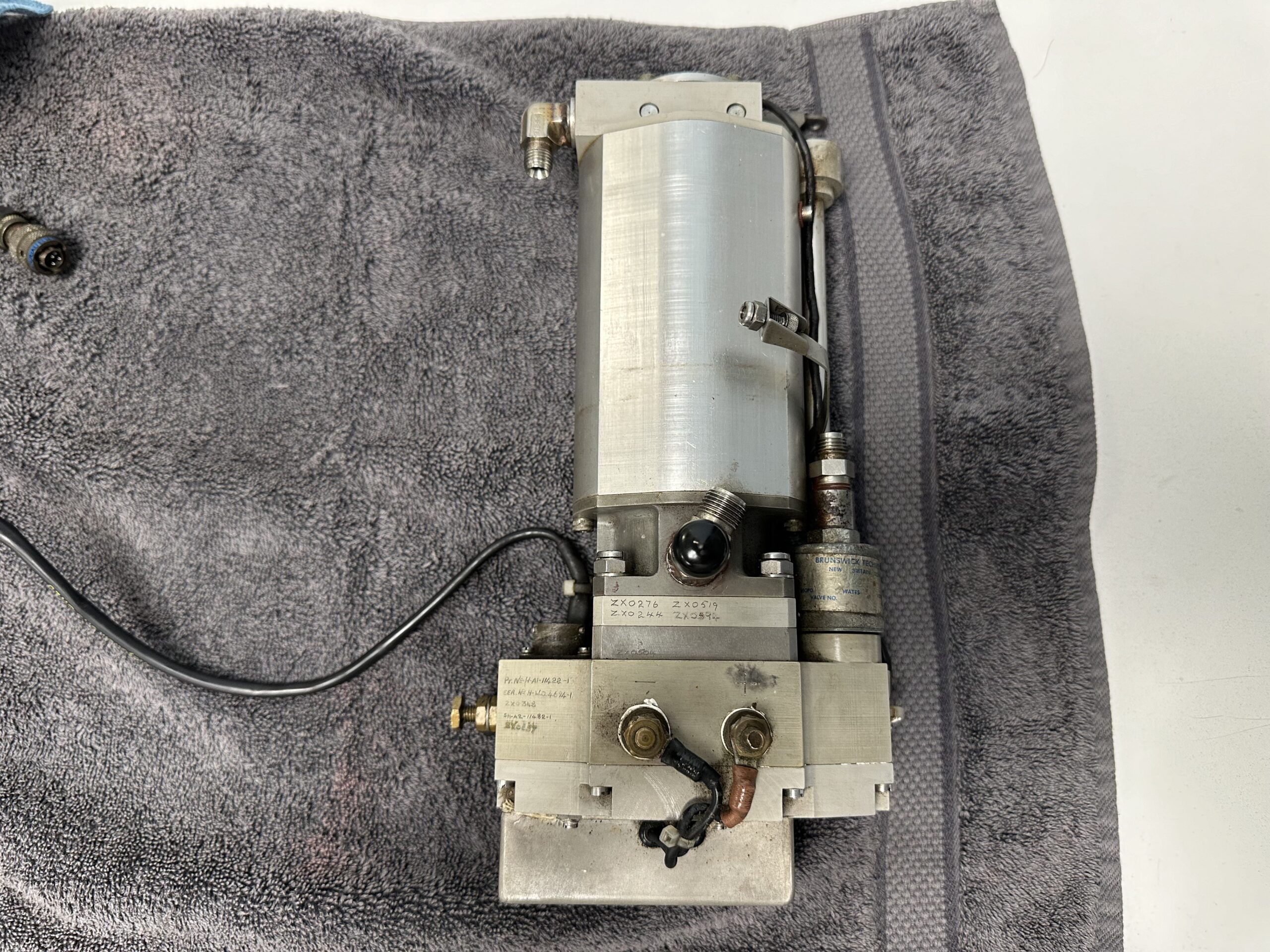

KeymasterWe now have all the accessories and mounts removed from the turbine, leaving us with a 23kg core. Almost half the weight of the NPT301 is comprised of heavy accessories!

One of the next jobs will be to construct an engine service stand, which can cradle the turbine during maintenance. Will likely construct this out of marine grade plywood and give several coats of paint.

February 22, 2024 at 6:31 am #1326Benjamin Morgan

KeymasterFebruary 22, 2024 at 6:32 am #1329Benjamin Morgan

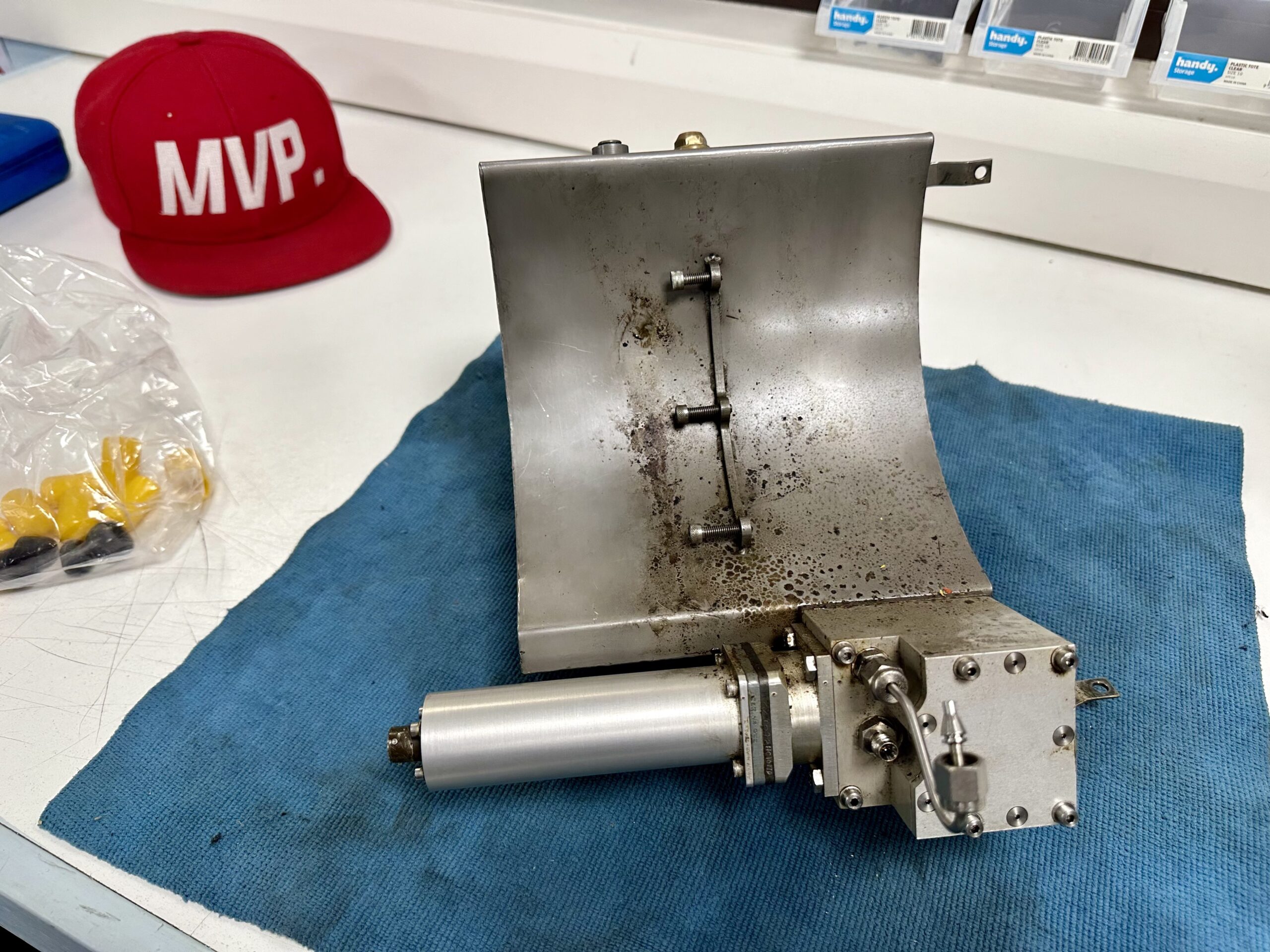

KeymasterOil tank reservoir (2.85litres) and oil pulse pump from the NPT301. The 12v pump supplies two turbine shaft bearings (front and rear) with a continuous flow of oil at one pulse per second (60 pulses a minute), independent of turbine speed. Pump volume supplied is 570ml per hour. Oil supply is total loss and system has 2 hours endurance with 30 min reserve.

-

AuthorPosts

- You must be logged in to reply to this topic.